Laboratory Tours

Time: 2 PM – 4 PM on Monday October 01, 2018

Meeting point: In front of the University of Kentucky (UK) Main Building.

A shuttle will leave at 1:30 PM from the High Street entrance of Lexington Convention Center to the

UK Main Building.

The ISM Workshop participants who are interested in the laboratory tour will be able to walk to the meeting point. When driving directly to the UK campus, Parking Structure #5 will be the most convenient parking option. Please check here for information and parking fees.

After the Laboratory Tour, a shuttle bus will be provided to return to the Lexington Convention Center.

Sustainable Machining Research Laboratory

Director: I.S. Jawahir, James F. Hardymon Chair in Manufacturing Systems and Professor of Mechanical Engineering

The Machining Research Program at the University of Kentucky is an interdisciplinary activity with active participation of several faculties with diverse manufacturing background from three engineering departments in the College of Engineering. A number of graduate students and postdoctoral researchers conduct research in a range of project areas in machining. Many of the current projects are externally funded. As part of the international cooperative research during the last few years, a number of overseas researchers have visited and worked with our research group on many project areas in machining. The current machining research program is focused on two major thrust areas:

- Development of Predictive Models for Sustainable Machining Operations

- Integrated Systems for Optimum Machining Performance

Key projects include:

- Sustainable (dry, near-dry and cryogenic) machining of aerospace Ti alloys

- Near-dry and cryogenic burnishing of Mg, Co-Cr-Mo and Ti alloys for biomedical applications

- Cryogenic drilling of CFRP for improved surface integrity and functional performance

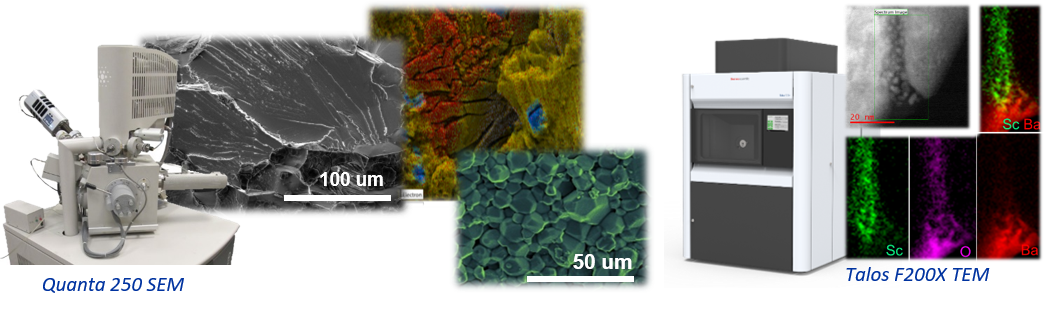

Electron Microscopy Center (EMC)

Director: Dr. T.J. Balk, William T. Bryan Professor of Materials Science & Engineering

The Electron Microscopy Center (EMC) is a multi-user shared equipment center that serves the entire university community and industries locally and nationwide. A wide variety of projects in the areas of sustainable manufacturing and energy generation have been supported through state-of-the-art characterization of microscopic features. The Electron Microscopy Center offers access to multiple characterization and sample preparation techniques. Four Scanning Electron Microscopes (SEMs), a Transmission Electron Microscope (TEM) and a dual beam (Focused Ion Beam/SEM) are available at the EMC, in addition to specimen preparation stations. Equipment at the EMC allow for elemental analysis, crystal orientation mapping and electron diffraction.

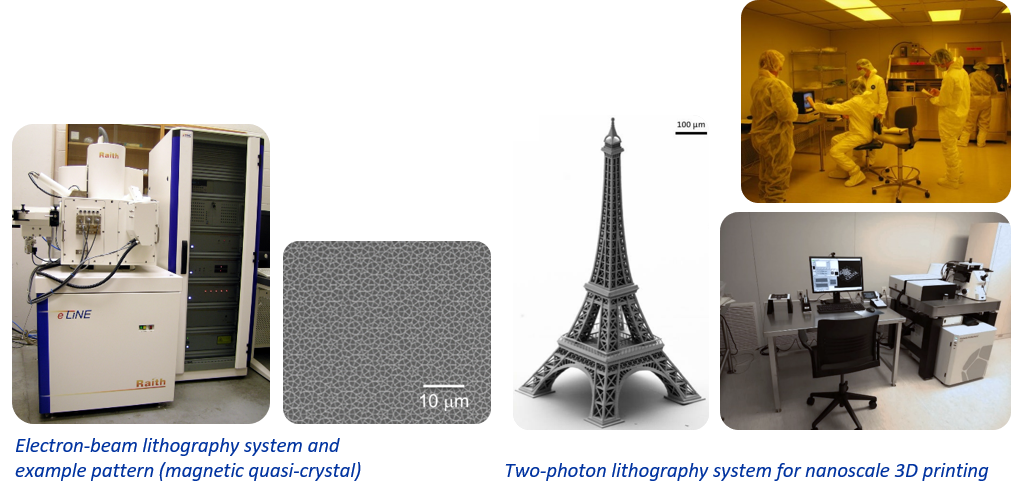

Center for Nanoscale Science and Engineering (CeNSE)

Director: Dr. J. Todd Hastings, Reese Terry Professor of Electrical Engineering

The Center for Nanoscale Science and Engineering (CeNSE) at the University of Kentucky (UK) is a

cutting-edge shared-use facility located in UK’s Advanced Science and Technology Commercialization Center (ASTeCC). CeNSE is part of Kentucky Multiscale a site in the NSF National Nanotechnology Coordinated Infrastructure program. CeNSE serves a multidisciplinary group of faculty, students, and staff with a shared vision for studying and developing nanoscale materials and devices. Center participants hail from the colleges of Engineering, Pharmacy, Medicine, Arts and Sciences, and Agriculture, Food and Environment. They are joined by external users from Kentucky universities and companies, including several startup companies housed in ASTeCC. Research conducted within the center targets a number of nanoscience applications in energy, bioengineering, medicine, computation, communication, and data storage. CeNSE manages a nanofabrication facility with extensive infrastructure including a class 100 cleanroom. In addition to standard planar processing capabilities, the center offers electron-beam lithography and a brand-new system for three-dimensional, two-photon lithography that can serves a deep sub-micron 3D printer. The center is led by Dr. J. Todd Hastings, director, with assistance from Drs. Vijay Singh and Zhi Chen. The center is staffed by a research engineer and student technicians who provide process consulting and training for users.